Contract for film/sheet prototype and mass production

Proximity to manufacturing site Film/sheet prototyping possible!

Speaking of sheet prototypes, the width of 30 to 300 mm is typical, and up to a maximum length of 800 mm. In addition, it is a facility that is capable of making the much-requested demanded grade of the 3-layers co-extrusion construction. We additionally support high-precision prototypes and mass production studies.

Feature

T-die width = 1,000 mm

Film/sheet from single layer to a co-extrusion of 5-layers of resin can be formed.

It is possible to make prototypes of film/sheet from single layer to a co-extrusion of 5 layers of 3 resins, and it is possible to make various prototype films/sheets according to customer’s request. In addition, trial resin can be used for general-purpose plastics, in-line measurement of highly-engineering plastic film thickness, lamination of protective films, thermal lamination, and various evaluation services.

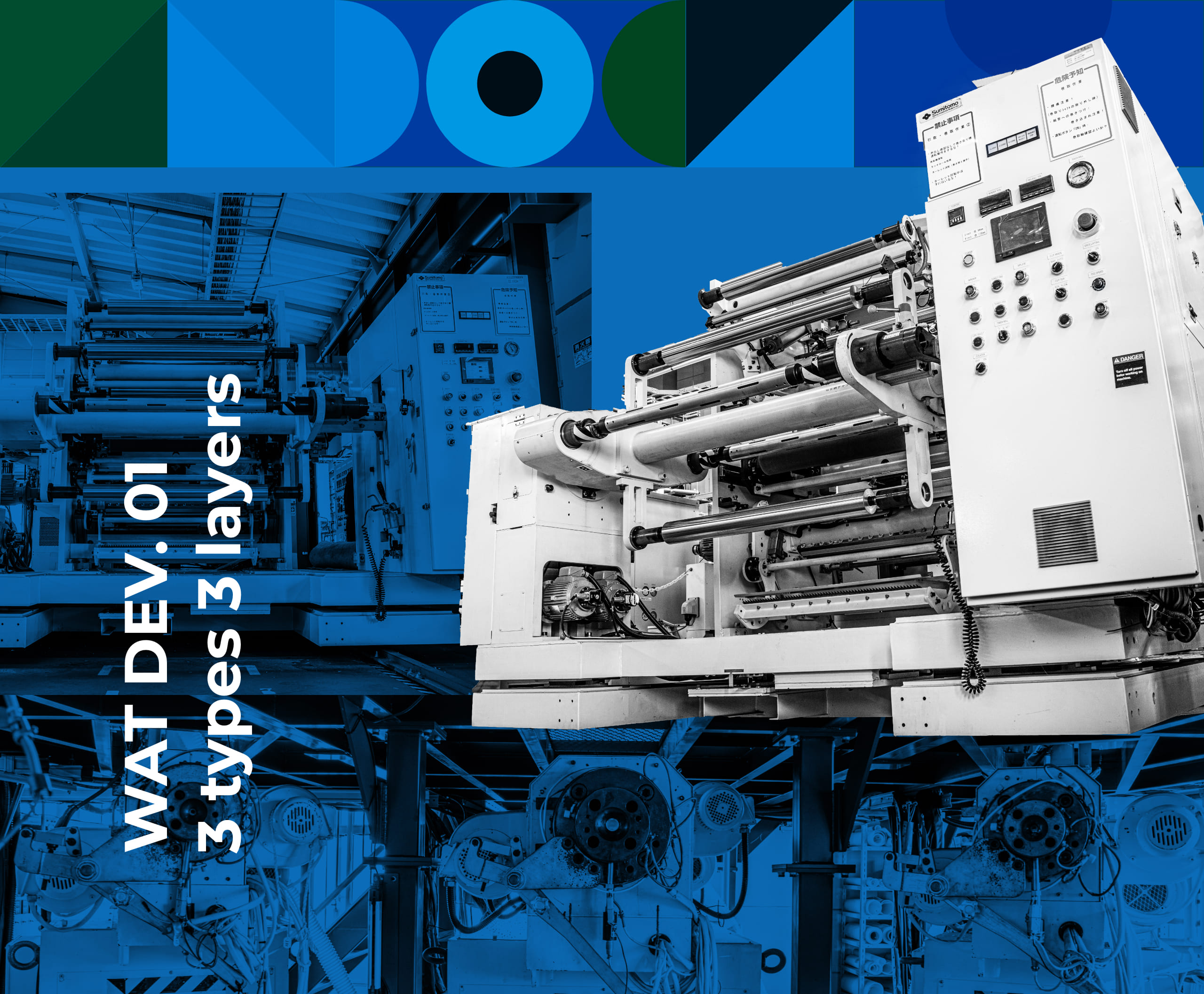

Capable of molding films/sheets from a single layer to a co-extrusion of 5 layers of 3 resins

It is possible to extrude film/sheet from single layer to 5 layers of 3 resins. In addition, prototype resins can be widely used for general-purpose plastics, engineering plastics, and highly engineered plastics. (Details can be discussed individually)

Thickness measurement by X-ray even for prototyping

With the optical co-extruded prototype film, it is possible to make high-quality prototypes as a step to mass production by measuring the thickness in detail at the prototype stage.

Application of Protection Film

By attaching a protective film, it is possible to prevent scratches caused by handling after trial production.

Optical films/sheets can also be manufactured by extrusion molding as a prototype.

Optical films/sheets can be extruded using an optical multi-layer prototype. Unlike general-purpose machines, we provide high quality optical films/sheets.

3 types blend We have also a blender machine.

It is possible to blend dry resin pellets. Additives and coloring are also available. However, liquids and powders cannot be used.

Thermal lamination

It is possible to bond various materials with each other while heating them. The base material can be laminated using a thermoplastic base material.

Overview

Optical multilayer prototype

Up to a co-extrusion of 3 layers of resin / Thickness measurement / Double-sided protection / Applicable for optical applications / Blender for 3 types / Thermal lamination possible

Specification

| Name | Optical multilayer prototype extruder |

| Extruder | Non-vent L/D 36 |

| T-die (mm) | 1,000 mm |

| Screw diameter (mm) | Φ65mm x 1, Φ40mm x 2 |

| Extrusion temperature (℃) | Currently : about ~ 400℃ |

| Casting unit | Air chamber type, air knife type, rubber/metal nip type, UF roll/metal nip, metal/metal nip |

| Sheet width, thickness Width | up to 800 mm Thickness: up to 1,000 mm |

| Required raw material amount (kg) | 200 kg or more (consultation required) |

| Others | Feed block supports up to 3 types and 3 layers. Compatible with optical applications |

| Compatible with super engineering plastics (~about 400℃ as of now. We plan to be able to get up to about 400℃) For details, please contact us individually. (around March 2021 timeframe) | |

| Dehumidifying dryer, raw material mixture (main raw material + sub raw material 2 types 3 types mixing)/extruder | |

| Thickness measurement (X-ray in-line) | |

| Both sides can be protected | |

| Can be heat laminated | |

| Possibility to attend trials |

- TOP

- Development Division

- Contract for film/sheet prototype and mass production